Cooling systems are essential in multiple sectors, from the food industry to space air conditioning. Their proper functioning largely depends on the quality and durability of their components, many of which are metallic. In this article from Fiposa, you will learn about the main uses of metallic components in cooling systems, highlighting their functions, advantages, and the impact they have on the system’s efficiency and durability.

Components in cooling systems

Cooling systems work by transferring heat from one space or substance to a colder environment. To achieve this transfer, various components are used that must withstand high pressures, variable temperatures, and corrosion caused by chemical or environmental agents. This is where metal materials play a crucial role, due to their mechanical, thermal, and chemical properties.

Copper and aluminum tubes and pipes

One of the most common uses of metals in refrigeration and industrial cooling systems are the tubes and pipes through which the refrigerant flows. Copper is the preferred material for this function, thanks to its high thermal conductivity, corrosion resistance, and ease of welding or bending without losing its properties. Copper tubes allow the refrigerant to flow efficiently, facilitating heat transfer.

Aluminum is also used, especially in applications requiring lower weight or lower costs. Although it has lower thermal conductivity than copper, its corrosion resistance and ease of molding make it a valid alternative in heat exchangers or condensers.

Metal evaporators and condensers

Metal evaporators and condensers

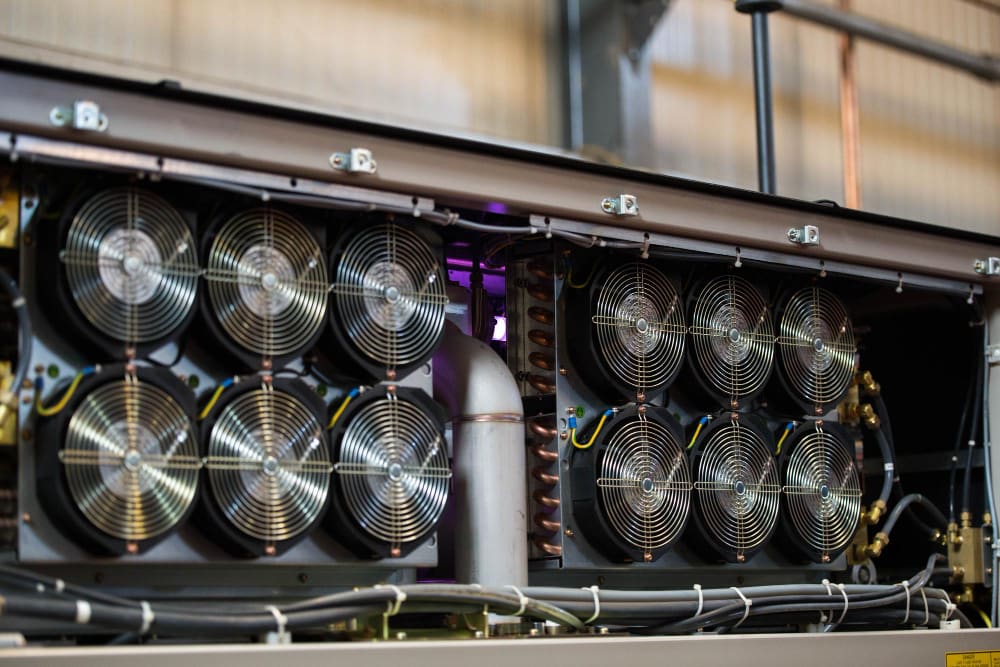

Evaporators and condensers are key components in cooling devices. In these, the refrigerant changes state to absorb or release heat, so thermal transfer must be optimal. Metals, mainly copper and aluminum, form the fins and tubes of these devices.

Metal fins increase the contact surface with the air, improving heat dissipation. Their manufacture using light and conductive metals ensures greater energy efficiency of the system and superior durability compared to other materials.

Compressors and internal metal components

The compressor is the heart of a cooling system. Its function is to compress the refrigerant to increase its pressure and temperature before it passes to the condenser. Most compressors are made from metals such as stainless steel or resistant alloys to withstand extreme internal pressure and temperature conditions.

Additionally, the internal compressor components, such as pistons, valves, and shafts, require metal materials that guarantee resistance to wear and continuous mechanical stress. Without these metal components, the compressor’s service life would be severely reduced.

Metal valves and connections

Valves regulate the refrigerant flow within the system and must provide a hermetic seal and reliable operation over time. Metal valves, commonly made of brass or stainless steel, are the most used due to their mechanical strength and corrosion resistance.

Metal connections, such as flanges, nuts, and fittings, are essential for assembling the various system components. These parts ensure the refrigerant flows without leaks and withstand internal pressure without deformation.

Metal trays and structures

Cooling systems usually have metal trays or structures that support the main components, such as the compressor, pipes, and pumps. These structures are generally made of galvanized steel or stainless steel, materials that provide rigidity and corrosion resistance, ensuring mechanical stability and prolonging the system’s lifespan.

Advantages of using metals in cooling systems

The use of metallic components offers multiple advantages:

- Durability: Metals resistant to wear and corrosion guarantee a long system lifespan.

- Thermal conductivity: Metals like copper and aluminum facilitate efficient heat transfer.

- Mechanical strength: They withstand internal pressures and stresses without deforming.

- Easy maintenance: Many metals allow easy repairs or replacements, such as welding or threading.

- Adaptability: Metals can be molded or manufactured in different shapes and sizes to fit system needs.

Metallic components are essential pillars in cooling systems, ensuring strength, efficiency, and durability. From the tubes where the refrigerant circulates to the structures that support the entire system, the proper use of metals such as copper, aluminum, and steel is fundamental for the correct operation and extension of these systems’ useful life.

Understanding their uses and advantages allows technicians and designers to optimize cooling installations, ensuring efficient performance and easier maintenance over time. Thus, metals are not only a physical component but also represent the foundation for reliable and sustainable cooling systems.