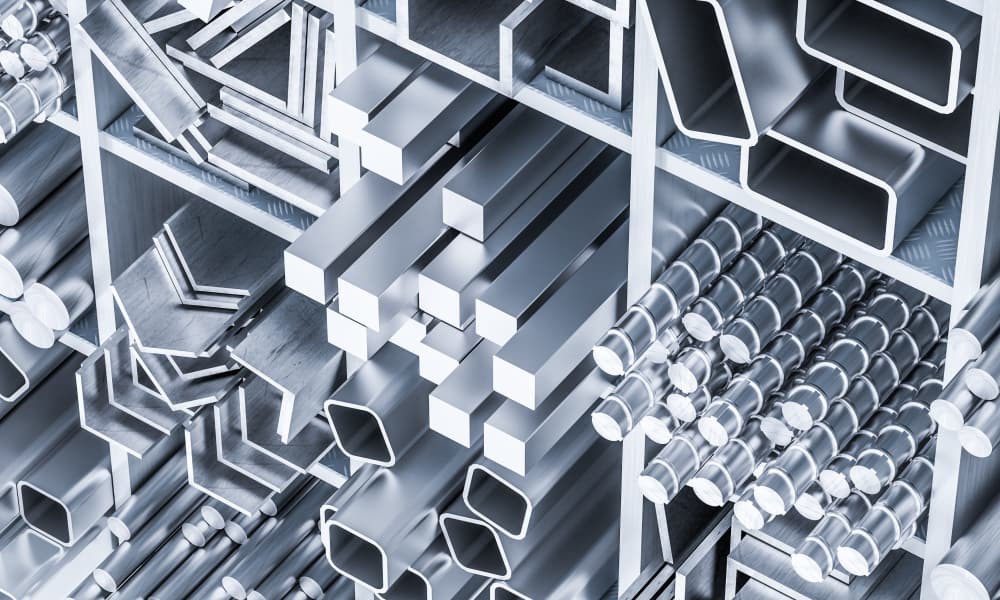

When it comes to choosing materials for a project—whether in construction, industrial manufacturing, or product design—steel and aluminum are often the two most popular options. Understanding the difference between aluminum and stainless steel is key to making sound technical decisions and optimizing resources in any type of application. That’s why, in this article from Fiposa, we compare steel and aluminum in detail to help you make an informed decision suited to your project’s needs.

Physical and Mechanical Properties

Steel is an alloy of iron with a small amount of carbon that gives it great strength and hardness. There are different types of steel (stainless, galvanized, structural, etc.), each with specific properties. In general, steel is denser and heavier than aluminum but also stronger in terms of tensile strength and resistance to deformation. This makes it the preferred option for heavy-load structures such as bridges, skyscrapers, industrial tools, and heavy machinery.

Aluminum, on the other hand, is a lightweight metal, with approximately one-third the weight of steel. Although not as strong, it offers an excellent strength-to-weight ratio, making it highly valued in sectors where weight is a key factor, such as the aerospace industry, transportation, and the manufacture of bicycles or electronic components. Moreover, it is more malleable and easier to work with, which allows for the design of complex parts with less effort.

Durability and Corrosion Resistance

One of the key factors when choosing between steel and aluminum is the environment in which the material will be used. Carbon steel, for example, is prone to rust if not properly protected with paint, galvanization, or other treatments. However, stainless steel contains chromium, which gives it excellent corrosion resistance, even in extreme conditions such as marine or high-humidity environments.

Aluminum, by contrast, naturally forms a protective oxide layer that shields it from corrosion. This property makes it especially suitable for outdoor use, façades, boats, portable structures, and products exposed to the elements. However, in highly salty environments or when in contact with certain metals, aluminum may suffer from galvanic corrosion, so certain precautions must be taken during installation.

Whether you’re considering aluminum or stainless steel, both materials offer durability in harsh conditions, though they behave differently depending on the environment.

Weight and Ease of Transport

Weight and Ease of Transport

Weight is one of the main factors that can tip the balance. As mentioned, aluminum is significantly lighter, which reduces transportation costs, eases handling, and enables the creation of lighter structures. This also translates into lower energy consumption in vehicles or aircraft, directly impacting the efficiency and sustainability of many products.

Steel, being heavier, requires more resources for transport and handling. However, its greater strength allows for the use of less material in some cases, partially offsetting its weight.

Cost and Availability

In general terms, steel is more economical than aluminum. Its extraction and production processes are more efficient and more widespread globally, making its price more stable and accessible. Therefore, in projects with tight budgets or when large quantities of strong material are needed, steel is often the preferred choice.

Aluminum, while more expensive, can be a cost-effective investment in the long term due to its durability, low maintenance, and lightness. Additionally, its high recyclability and lower environmental impact during transport are increasingly valued factors in decision-making.

Which One Should You Choose?

The best choice depends on the type of project you’re working on. If you’re looking for structural strength, low cost, and can handle a heavier material, steel will be the right option. It’s ideal for fixed constructions, support structures, and mechanical tools.

If your priority is low weight, corrosion resistance, or you’re working in applications where aesthetics and ease of handling matter (such as product design, modern furniture, or vehicles), aluminum might be the better choice.

There is no clear “winner” between steel and aluminum: it all depends on your specific needs. Choosing between stainless steel or aluminum requires considering factors such as environment, budget, end use, and load conditions.

In many cases, it may even be advisable to combine both materials to take advantage of the best qualities of each. The key is to carefully evaluate the advantages and limitations of each metal before making a decision.