Batch traceability for metal parts is a key aspect in sectors such as manufacturing, automotive, aerospace, construction, and capital goods. Ensuring that each part can be identified, traced, and linked to its origin, production process, and quality controls is not only a regulatory requirement in many cases, but also a fundamental tool for ensuring quality, safety, and operational efficiency.

Implementing an effective traceability system allows companies to have greater control over their production, respond quickly to incidents, and improve the trust of customers and regulatory bodies. In an increasingly demanding industrial environment, traceability is no longer an option but a strategic requirement.

What is batch traceability and why is it key in metal parts?

Batch traceability is the ability to identify a set of parts manufactured under similar conditions and track their journey throughout the entire value chain. In the case of metal parts, this means being able to link each batch to the raw materials used, the manufacturing processes, the controls performed, and the final destination of the product.

This type of traceability is especially relevant for metal parts due to the critical nature of their applications. A failure in a part can have serious consequences, making it essential to quickly determine its origin and extent . Batch traceability allows for isolating problems, reducing the impact of recalls, and preventing unnecessary production downtime.

In addition, many quality standards and industry regulations require documented traceability systems. Complying with these requirements not only avoids penalties, but also improves internal organization and facilitates audits, certifications, and continuous improvement processes.

How is batch traceability implemented in metallurgical processes?

How is batch traceability implemented in metallurgical processes?

Implementing batch traceability for metal parts requires integrating control from material receipt to final product shipment. It all begins with identifying the raw material and assigning a batch code that accompanies the material throughout the entire production process. This code must be maintained and linked to each stage of transformation, machining, heat treatment, or surface finishing.

During manufacturing, it is essential to record which operations are performed on each batch and under what conditions. This includes information about the machines used, process parameters, dates, shifts, and responsible parties. In many cases, metal parts are grouped into batches to optimize production, making it even more important to maintain rigorous control over the associated information.

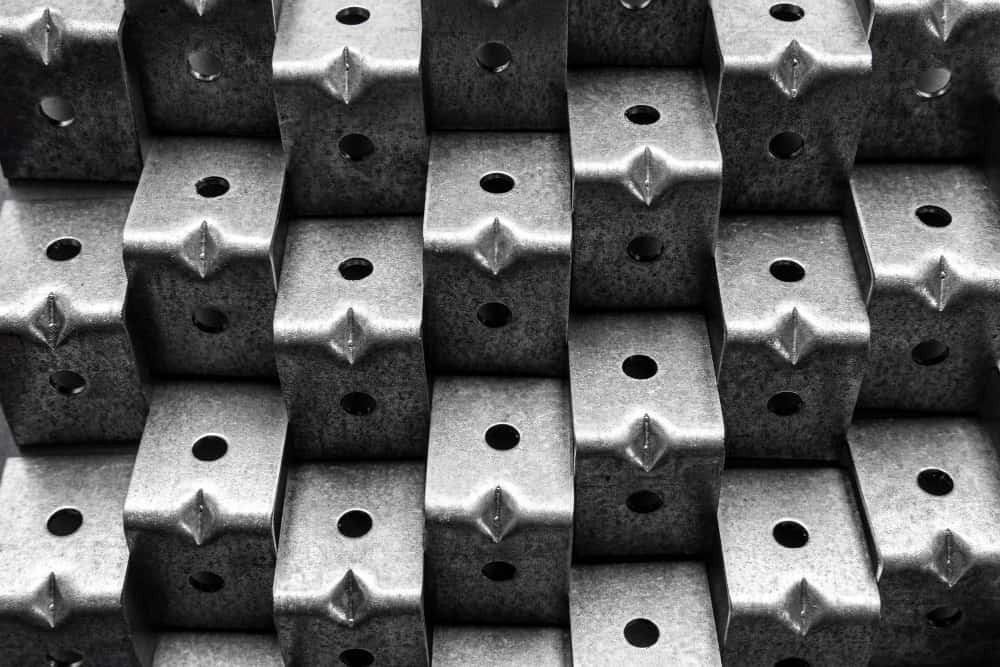

Physical identification of parts or batches can be carried out using different methods, such as laser marking, engraving, durable labels, or Data Matrix codes. The choice of system depends on the size of the part, the material, the usage environment and customer requirements. The important thing is that the identification is legible, durable, and compatible with the company’s management systems.

Digitalization plays a key role in this process. ERP, MES, or quality management systems allow for the centralization of traceability information and provide quick and reliable access to it. A well-integrated system reduces manual errors, improves real-time traceability, and facilitates decision-making.

Benefits of effective batch traceability in metal parts

Having a well-implemented batch traceability system provides direct benefits at both the operational and strategic levels. From a quality perspective, it allows for the early detection of deviations and the analysis of their root cause, preventing problems from recurring. It also facilitates the management of non-conformities and complaints, since it is possible to accurately identify which parts are affected.

In terms of efficiency, traceability improves inventory control and reduces waste, as it allows you to know exactly which materials and parts are available, their condition, and which orders they are associated with. This translates into better planning and reduced operating costs.

From the customer’s perspective, batch traceability conveys trust and professionalism. Being able to offer detailed information about the origin and manufacturing process of metal parts is an added value that sets a company apart in a competitive market. Furthermore, it facilitates compliance with contractual and regulatory requirements, especially in highly regulated sectors.